The history of Glock and their introduction to the Greek market

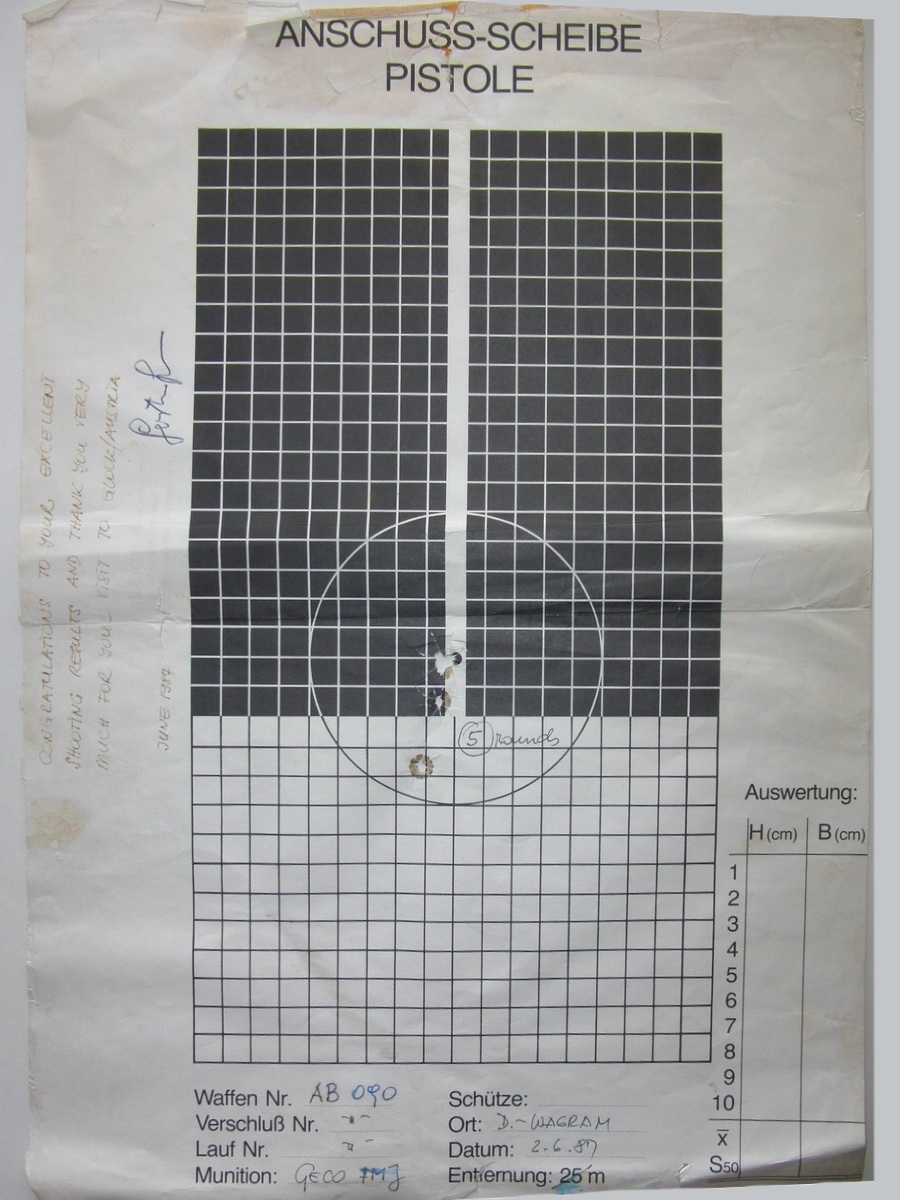

In April 1987, it was the month and year of the establishment of the Hellenic Arms Company. The aim was to import and trade unique equipment in the Greek market. One of the first and also key companies added to our portfolio was Glock. Ges.m.b.H. In June 1987, after communication about our cooperation, a visit to the plant in Austria was held for presentation and testing of Glock 17. The manager and then general manager of the company, Georgios Michalopoulos, having previous experience and contact with the weapons, described Glock as unique in the world (which is still the case today). The shots performed were both speed and precision, with the weapon not showing signs of "fatigue".

After this successful test, our collaboration with Glock Ges.m.b.H. had officially begun. The road was long but initially difficult because it was the first polymer gun manufactured in the world and therefore one could not trust a plastic frame! After exhaustive tests and tests, the first in Greece and Europe, made at the premises of the (then) Underwater Demolition Unit, was the supply of the first G17 Amphibious. We can say that the gun was "tortured" mercilessly by U.D.U executives in order to prove its advertised endurance in all conditions, and to be 100% sure of the warrior and its operation in combat conditions!

Undoubtedly, the GLOCK pistol is considered to be one of the best fighting pistols ever built, if not the best.

His story began in the early 1980s when the Austrian Army decided to change pistol. This contest, casting on the interest of Gaston Glock, who, although not involved in the manufacture of firearms, had excellent knowledge and manufacturing experience in combining polymeric materials with metal.

The result was one of the most important discoveries in the technology of firearms in recent years. With its polymeric frame, the GLOCK 17 pistol was lightweight in weight while at the same time it had the highest capacity magazine than any other pistol in its class. The pistol did not have an external safety lever, or "decocker" or any other mechanisms that need to be deactivated prior to firing. So it was faster, simpler and safer than any other pistol.

Its unexpected success in the global market is due to the following advantages over competition pistols.Less weight than any other pistol in its class

- Large magazine capacity (for GLOCK17, 17 to 33 cartridges).

- It is safe, fast and simple to handle.

- It has easy solution / grouting / maintenance, without tools, up to the 5th stage.

- It has fewer pieces than any other pistol and the minimum probability of failure to wear from a component.

- It provides complete switching of all parts between weapons without requiring any interference or conversion.

- It throws all kinds and types of ammunition of the corresponding caliber without difficulty.

- Its barrel, due to its construction, has a lifetime of more than ten times that of other gun guns.

- It has a special surface treatment of "TENIFER *" which gives the metal hardness (64 HRC) roughly equal to diamond (70 HRC) and 100% resistance to corrosion by any corrosive substance (seawater, sweat, blood, etc.).

- It also fits in semiautomatic mode, in the water and outwards, which no other pistol does (amphibious version).

- It works at temperatures from -50ο C to + 200ο C, without malfunctions.

- Its body is made of special polymeric material with greater resistance to stress even from steel.

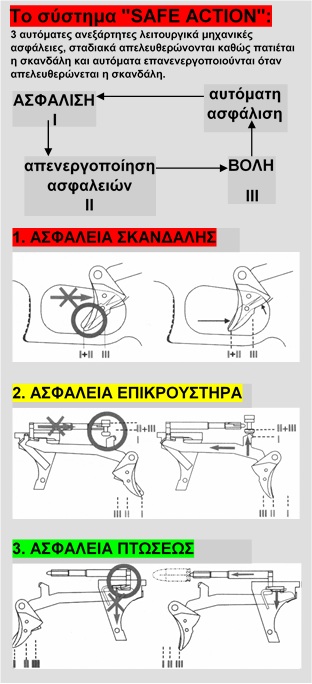

- It has three internal fuses. It is impossible for the weapon to detonate if the operator does not press the trigger.

- It has a special fall safety which does not allow the gun to fire, even from a high height drop.

In short, the pistol combined the advantages of two different systems,

1) of the reel (simple to operate, reliable)

and

2) of the pistol (maximum firepower, quick refill).

This was the birth of GLOCK's security system, known as "SAFE ACTION".

At the push of the trigger, three independent fuses are deactivated progressively, and after the firing

and the release of the trigger, are automatically activated again.

Although we are in the fifth generation of "improvements" of GLOCK guns, the basic design remains the same.

Simple and reliable.

The only thing that has changed significantly is the incredible variety of models and diameters available

GLOCK guns and metalworking.

* Tenifer was used until 2011 as treatment method (Gen3) because the US Department of the Environment has raised the issue of the chemicals used. From 2011 and on, a new method was used that Glock referred to as "Cold Nitride", which is essentially the Melonite method, which is similar to Tenifer but uses slightly different chemicals and manufacturing temperatures. In the 5th generation, Glock is a new approach to nDLC (near Diamond-Like Carbon) based on the same principles. Any metal treatment is done in a 0.5 mm layer, and on top of the painting method with the parkerize method. Even if paint dies, the gun is protected from processing.